Yes, the 7.3 Powerstroke engine does have an injection pump. It is a hydraulically operated unit that delivers fuel to the engine’s cylinders.

The 7. 3 Powerstroke injection pump plays a crucial role in the engine’s performance, ensuring proper fuel delivery and combustion for optimal power output. Understanding the function and significance of the injection pump is essential for maintaining and enhancing the engine’s efficiency.

We will delve into the specifics of the 7. 3 Powerstroke injection pump, its operation, maintenance, and potential issues that owners may encounter. Whether you are a 7. 3 Powerstroke owner or an enthusiast seeking comprehensive insights, this guide will provide valuable information on this vital engine component.

The Heart Of The Matter: 7.3 Powerstroke Fuel System

If you’re a diesel truck enthusiast, you know the 7.3 Powerstroke engine is one of the most iconic engines out there. With its powerful performance and reliability, it’s no wonder the 7.3 Powerstroke is still a popular choice for truck owners today. But when it comes to the fuel system of this engine, there’s one question that often comes up: does a 7.3 Powerstroke have an injection pump?

Key Components

Before we can answer that question, let’s take a look at the key components of the 7.3 Powerstroke fuel system. The fuel system of this engine is made up of several parts, including:

- Fuel tank

- Fuel pump

- Fuel filter

- High-pressure oil pump

- Injector control pressure regulator (ICP)

- Injectors

Fuel Delivery Mechanics

The fuel delivery mechanics of the 7.3 Powerstroke engine are quite different from those of a gasoline engine. Instead of using spark plugs to ignite the fuel, the diesel fuel is injected directly into the engine cylinders. But how does the fuel get to the cylinders in the first place?

The fuel tank sends diesel fuel through the fuel lines to the fuel pump, which then pressurizes the fuel and sends it through the fuel filter. From there, the fuel is sent to the high-pressure oil pump, which pressurizes the oil and sends it to the injectors. The ICP regulates the pressure of the oil going to the injectors, ensuring that the right amount of fuel is injected into the engine cylinders at the right time.

So, does a 7.3 Powerstroke have an injection pump? The answer is no, not in the traditional sense. Instead, the high-pressure oil pump is responsible for pressurizing the oil that is used to inject the diesel fuel into the engine cylinders.

Common Myths Around The 7.3 Powerstroke Injection Pump

A common myth surrounds the 7. 3 Powerstroke injection pump, with some believing it doesn’t have one. In reality, the 7. 3 Powerstroke does have an injection pump, crucial for delivering fuel to the engine efficiently. This misconception often leads to confusion among vehicle owners and enthusiasts.

Myth Vs. Reality

Origin Of Confusion

There are common myths surrounding the 7.3 Powerstroke injection pump that often lead to confusion among truck owners.

Myth Vs. Reality

Myth: The 7.3 Powerstroke does not have an injection pump.

Reality: The 7.3 Powerstroke does have an injection pump, which plays a crucial role in delivering fuel to the engine.

Origin Of Confusion

Origin: The confusion may stem from misinformation or misunderstanding of the engine’s components.

- Misconception: Some believe that the 7.3 Powerstroke relies solely on electronic fuel injection.

- Truth: The injection pump in the 7.3 Powerstroke is a mechanical fuel pump that operates independently of electronic controls.

Exploring The 7.3 Powerstroke’s Heui Injection System

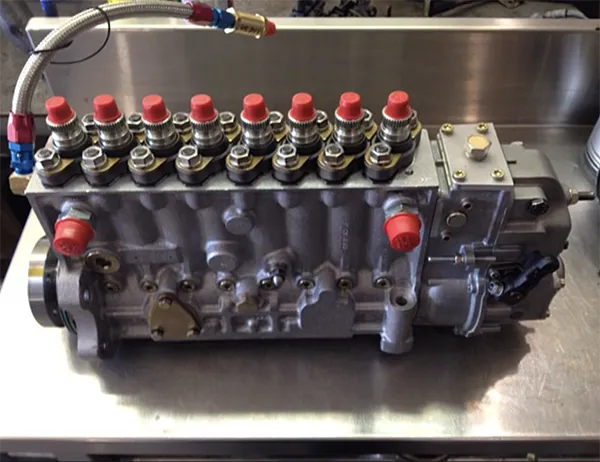

The 7.3 Powerstroke diesel engine is known for its reliability and longevity, but how does its injection system work? The 7.3 Powerstroke uses a HEUI (Hydraulic Electronic Unit Injection) system, which is different from traditional injection pumps. In this article, we will explore how HEUI works and the differences between it and traditional injection pumps.

How Heui Works

The HEUI system used in the 7.3 Powerstroke injects fuel into the engine cylinders at extremely high pressures. The fuel is pressurized by an engine-driven high-pressure oil pump and then sent to the injectors. The injectors are equipped with a solenoid that controls the injection timing and duration. The solenoid also opens the injector’s poppet valve, allowing the pressurized fuel to be injected into the cylinder.

The HEUI system uses hydraulic pressure to intensify the injection pressure, which means that the injection pressure can be much higher than the oil pressure. This allows for more precise fuel delivery and better engine performance.

Differences From Traditional Injection Pumps

Traditional injection pumps, such as those used in mechanical diesel engines, rely on a camshaft to create pressure in the fuel system. The camshaft pushes on a plunger, which pressurizes the fuel and sends it to the injectors. However, this system is not as precise as the HEUI system used in the 7.3 Powerstroke.

The HEUI system’s use of hydraulic pressure allows for more accurate fuel delivery and better engine performance. Additionally, the HEUI system has fewer moving parts than traditional injection pumps, which means that it is more reliable and requires less maintenance.

| HEUI | Traditional Injection Pump | |

|---|---|---|

| Pumping Mechanism | Engine-driven high-pressure oil pump | Camshaft-driven plunger |

| Injection Pressure | Can be much higher than oil pressure | Depends on camshaft design |

| Reliability | Less maintenance required | More maintenance required |

In conclusion, the 7.3 Powerstroke’s HEUI injection system is a high-pressure fuel delivery system that uses hydraulic pressure to intensify injection pressure. This system is more precise and reliable than traditional injection pumps, making it a popular choice for diesel engines.

The Role Of High-pressure Oil In Fuel Injection

The 7. 3 Powerstroke does have a high-pressure oil pump that plays a crucial role in fuel injection. This pump is responsible for supplying the necessary oil pressure to operate the fuel injectors efficiently. Without a properly functioning high-pressure oil pump, the fuel injection system may not perform optimally.

The Role of High-Pressure Oil in Fuel Injection\

Oil Pump Functionality

The 7.3 Powerstroke engine features a high-pressure oil pump that plays a crucial role in the fuel injection process. This pump is responsible for generating the high-pressure oil that is necessary for the proper functioning of the fuel injectors.

Impact on Fuel Injection

The high-pressure oil generated by the pump is used to actuate the fuel injectors, providing the force needed to inject fuel into the combustion chamber at the precise moment. This process ensures optimal engine performance and fuel efficiency.

In summary, the high-pressure oil pump in a 7.3 Powerstroke engine is essential for providing the force needed to actuate the fuel injectors, resulting in efficient fuel injection and optimal engine performance.

Comparing The 7.3 Powerstroke To Other Diesel Engines

Yes, the 7. 3 Powerstroke does have an injection pump. When comparing the 7. 3 Powerstroke to other diesel engines, its Bosch mechanical injection pump stands out for its reliability and ease of maintenance. This injection pump contributes to the 7.

3 Powerstroke’s reputation for robust performance and longevity.

Injection Systems In Other Models

When it comes to diesel engines, the injection system plays a crucial role in the overall performance and efficiency. The 7.3 Powerstroke is often compared to other diesel engines to determine its unique features and advantages. One key area of comparison is the injection system.

Many diesel engines, such as the Cummins ISB and the Duramax, utilize a common rail injection system. This system features a high-pressure fuel rail that supplies fuel to individual injectors. The fuel is pressurized by a high-pressure pump and then distributed to the injectors at the right time for optimal combustion. This type of injection system offers precise control over fuel delivery and can result in improved fuel efficiency and reduced emissions.

On the other hand, the 7.3 Powerstroke employs a different injection system known as the HEUI (Hydraulic Electronic Unit Injection) system. This system combines the benefits of both mechanical and electronic fuel injection. It uses high-pressure oil to hydraulically actuate the injectors, which allows for precise control over fuel delivery. The electronic control module (ECM) adjusts the injector timing and fuel quantity based on various engine parameters, resulting in efficient combustion.

Advantages Of The 7.3 Design

The 7.3 Powerstroke’s injection system design offers several advantages over other diesel engines. Here are some key benefits:

1. Reliability: The 7.3 Powerstroke’s HEUI system is known for its reliability and durability. The use of hydraulics reduces the stress on the injectors, resulting in longer lifespan and reduced maintenance costs.

2. Power and Torque: The HEUI system in the 7.3 Powerstroke delivers excellent power and torque, making it suitable for heavy-duty applications. The precise control over fuel delivery ensures optimal combustion, maximizing engine performance.

3. Fuel Efficiency: Despite its powerful performance, the 7.3 Powerstroke is also fuel-efficient. The combination of hydraulic and electronic fuel injection allows for efficient combustion, resulting in better fuel economy compared to some other diesel engines.

4. Easy Maintenance: The HEUI system in the 7.3 Powerstroke is relatively straightforward to maintain. The injectors are easily accessible, making servicing and replacement more convenient.

In conclusion, while many other diesel engines utilize common rail injection systems, the 7.3 Powerstroke stands out with its unique HEUI system. This design offers reliability, power, fuel efficiency, and ease of maintenance. Whether you’re looking for a dependable workhorse or a fuel-efficient powerhouse, the 7.3 Powerstroke’s injection system design makes it a standout choice among diesel engines.

Maintenance Tips For The 7.3 Powerstroke Fuel System

The 7.3 Powerstroke is a legendary engine known for its robust performance, and proper maintenance of its fuel system is crucial for ensuring its longevity and reliability. Here are some essential maintenance tips for the 7.3 Powerstroke fuel system to keep your engine running smoothly.

Routine Checks

- Regularly inspect the fuel filter for any signs of clogging or contamination.

- Check the fuel lines and connections for leaks or damage, ensuring a secure and proper fit.

- Monitor the fuel pressure to ensure it meets the manufacturer’s specifications.

- Inspect the fuel pump for any unusual noises or malfunctions.

Common Issues And Solutions

Issue: Clogged fuel filter leading to restricted fuel flow.

Solution: Replace the fuel filter at recommended intervals to prevent clogging.

Issue: Worn out fuel lines causing leaks or insufficient fuel delivery.

Solution: Regularly inspect and replace worn or damaged fuel lines to prevent leaks and ensure proper fuel flow.

Issue: Malfunctioning fuel pump resulting in inadequate fuel supply to the engine.

Solution: Replace the fuel pump if it shows signs of malfunction to maintain proper fuel delivery to the engine.

Upgrading The 7.3 Powerstroke For Performance

Enhancing the performance of your 7.3 Powerstroke engine can be achieved through various aftermarket upgrades and modifications. One key component to consider is the injection pump, which plays a crucial role in fuel delivery and engine efficiency.

Aftermarket Options

Upgrading the injection pump on a 7.3 Powerstroke can significantly improve fuel delivery and engine performance. Aftermarket options such as high-performance fuel pumps and modified injection systems are available to enhance power output and efficiency.

Considerations For Modification

- Choose a reputable manufacturer for aftermarket injection pump upgrades.

- Ensure compatibility with existing engine components.

- Consider the specific performance goals of the vehicle.

- Consult with a professional mechanic for installation and tuning.

Real World Experiences: Owners’ Tales

Case Studies

A 7.3 Powerstroke’s injection pump plays a crucial role in its performance.

Let’s dive into some real-life accounts from owners who have experienced firsthand the significance of the injection pump.

Expert Opinions

Experts emphasize the injection pump’s impact on a 7.3 Powerstroke’s overall functioning.

Let’s explore what professionals have to say about the injection pump in this powerful engine.

Conclusion

To sum it up, the 7. 3 Powerstroke engine does indeed have an injection pump. This crucial component plays a vital role in delivering the precise amount of fuel to the engine, ensuring optimal performance and efficiency. Understanding the function and importance of the injection pump can help owners and enthusiasts maintain and troubleshoot their 7.

3 Powerstroke engines effectively. So, whether you’re looking to upgrade or resolve any issues, having knowledge about the injection pump is essential. Keep your engine running smoothly with proper care and maintenance!